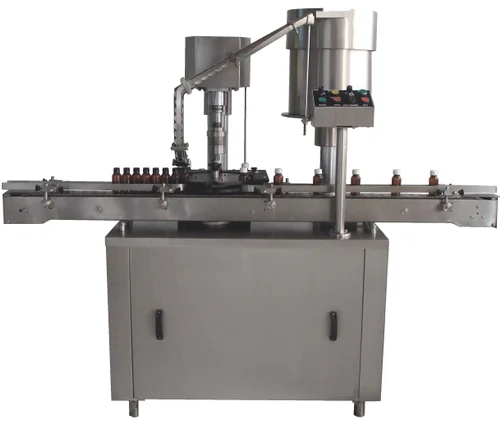

Home » Products » Capping Machine » Automatic Multi Head Screw/ROPP Cap Sealing Machine

When caps are placed in an orientation unit, they automatically align themselves correctly before going through the delivery chute. The bottle enters beneath the sealing head, which is made up of four rollers in total. Two rollers correctly skirt, spin, and seal the cap while another two rollers thread the bottle perfectly in accordance with the diameter of the neck. Following a sealing operation, the bottle travels with the aid of an exit star wheel and the sealing head moves higher to make room for the following operation on the conveyor belt.

The machine is equipped with a turntable, a S.S. slat conveyor belt, a feed worm, a bowl and chute, an infeed and exit star plate, a back guide, an easy-to-reach small panel, and no sealing system or container. With the aid of an automated system, the damage cap quantity may be decreased. The sealing unit and cap orientation unit are installed on two pillars that are in turn supported by the top plate. Every exposed section of it is composed of S.S. – 304. Its height may be changed to effectively synchronise with other machines.

| Model No. | LRCS 45 | LRCS 100 | LRCS 150 | LRCS 200 |

|---|---|---|---|---|

| Capping Heads | 1 Heads | 4 Heads | 6 Heads | 8 Heads |

| Output/ Min | 40-50 VPM | 60-80 VPM | 130-150 VPM | 180-200 VPM |

| Power Characteristics | Single Phase | 440v 3 Phase 50Hz 4 Wire System | 440v 3 Phase 50Hz 4 Wire System | 440v 3 Phase 50Hz 4 Wire System |

| Cap Size | 22mm / 25mm / 28mm | 22mm / 25mm / 28mm | 22mm / 25mm / 28mm | 22mm / 25mm / 28mm |

| Filling Accuracy | ±1 % | ±1 % | ±1 % | ±1 % |

| Net Weight (Appx.) | 250 kgs | 550 kgs | 870 kgs | 950 kgs |

| Machine Length | 1400mm | 1600mm | 1700mm | 1700mm |

WhatsApp us